Tubes by Type

Tubes by Type

Steel Tubes are the Tubes made by the process of hot extrusion of billets and hollow

forming, followed by cold working.

Precision Steel Tubes are hardened steel tubes, using precision heating, hence the name.

The precision heating helps in altering the properties of the material in terms of hardness,

strength, toughness, ductility and elasticity. The surface of metal consists of crystallites,

which get realigned subject to specific temperature over specific period of time,

thus causing the alteration in properties of the metal.

Precision Tubes are majorly used in Plants in Boiler tubes, heat exchange tubes, super-heater

tubes and in automobiles as chassis tubes and steering columns.

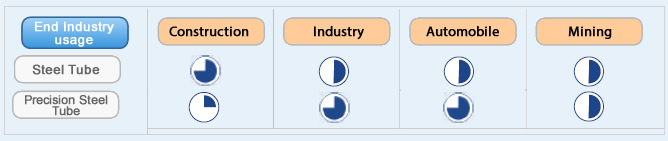

Tubes usage by End Industry

What are advantages of butt welding over flanges ?

• Flanges connect pipes by bolting them together, whereas butt weld fittings connect pipes by welding them together.

• Depending on size, butt weld fittings require 10% to 75% less material than a flanged connection, which means lower material cost and lower weight.

• Welded construction permits greater freedom in designing a layout; this system uses less space, is more compact, and has greater strength.

• Butt weld fittings provide optimum flow characteristics, without pockets or sharp corners, creating less frictional resistance, no pressure loss, less turbulence